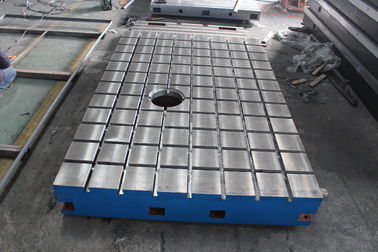

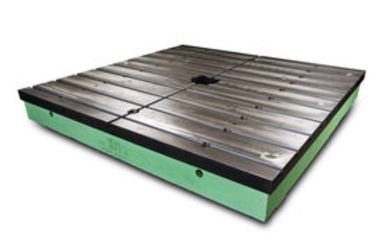

Base Plate With T-Slots Grey Cast iron Precision Tee-Slotted Table

cast iron T slot bed plates are manufactured from high-density special cast iron with added steel. These plates allow for a wide range of ‘work-holding’ solutions. Standard plates have a Brinell hardness of approx. 180 – 200 HB and a tensile strength of approx. 260 – 300 N/mm2.

T slot bed plates are cast in a special process that guarantees the least possible tension within the cast material, thus ensuring optimal rigidity and stability of the plate. The plates are specially designed to suit the customer's requirements. The design, dimensions and load capacity of the plate can be adapted to the size and weight of the workpieces to be held.

A substructure of T-shaped reinforced ribbing lends the plates a high inherent rigidity. The plates can be adapted to load requirements via the number of ribs used and the manner in which they are deployed. The size of the T-slots in the plates is determined by the tensile and compressive forces to which they will be subjected.

All standard sizes 14, 18, 22, 28, 36 or 42 can be manufactured, with fits in terms of DIN 650 ranging from H 7 to H 12.

T-slots in special or intermediate sizes can be provided. The distance between T-slots in standard plates is usually 150, 200, 250 or 300 mm.

Where individual plates are combined to form floor plates, dimensions are such that the distance between the T-slots is half the distance to the butt joint. This ensures that the distance between the T-slots remains constant across the entire surface. The distances between the slots as well as the clamping options can also be tailored to suit your requirements.

Depending on the customer specifications, the plates can have horizontal slots, threaded, fit or marking bores or apertures. We can also install zero-point spring-loaded systems.

Depending on their application, the plates can be made oil- and water-tight and fitted with an appropriate drip channel. The choice of alignment elements depends on the type of installation and the load on the plates.

Precision: According to the national standards measurement examination regulations execution,

respectively is 1,2,3, fine polish.

| Specification (mm) |

Flatness tolerance (um) |

| |

Grade1 |

Grade2 |

Grade 3 |

Finihs plane |

| 400x400 |

12 |

24 |

|

|

| 600x400 |

14 |

28 |

|

|

| 800x500 |

16 |

32 |

80 |

|

| 900x600 |

16 |

32 |

80 |

|

| 1000x750 |

18 |

36 |

90 |

|

| 1000x1000 |

20 |

39 |

96 |

|

| 1500x1000 |

25 |

48 |

120 |

|

| 2000x1000 |

26 |

52 |

129 |

|

| 2000x1500 |

|

56 |

140 |

|

| 2000x2000 |

|

60 |

152 |

230 |

| 2500x1500 |

|

68 |

168 |

248 |

| 3000x1000 |

|

|

174 |

248 |

| 3000x2000 |

|

|

184 |

275 |

| 3000x3000 |

|

|

210 |

300 |

| 4000x1000 |

|

|

210 |

300 |

| 4000x2000 |

|

|

219 |

310 |

| 4000x3000 |

|

|

240 |

360 |

| 5000x2000 |

|

|

255 |

375 |

| 5000x3000 |

|

|

287 |

420 |

| 6000x2000 |

|

|

293 |

430 |

| 6000x3000 |

|

|

308 |

460 |

| 8000x2000 |

|

|

370 |

520 |

| 8000x3000 |

|

|

382 |

570 |

Nocie for use

1: To the best uniform use of the flat plate throughout, to avoid local grinding concave.

2: Keep the plate clean, prevent be wroned by iron scrap, sand ...

3: Put down workpieces on the plate gently, prevent the flat surface be impacted, once the plate surface hit the workpiece or other objects,repair impact and the convex part immediately.

4: Do not do any hammer work on the surface plate .

5: After use, should be clean it. If long time no use should not be coated with anti rust oil to prevent corrosion.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!