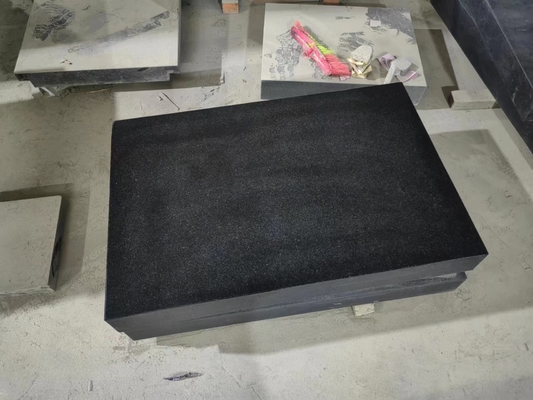

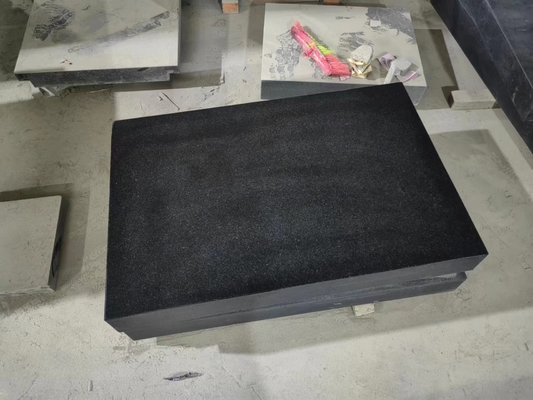

Smoothness Plate Used Testing Black Granite Surface Plate

Granite Surface plates are flat and plane surface used as a horizontal reference space for dimensional measurement, it’s a base for inspection, toolmaking, gauging, spotting, marking, and layout. They can be made from granite, metal, cast iron, or glass.

Serving as the benchmark for all measurements, surface plates play a pivotal role in quality checking and control. This surface is extremely flat that comes in Grade-00 to Grade-3 flatness accuracy substandard. Machine shops, all types of precise manufacturing, defense, automotive, and aerospace manufacturers require tight tolerances for machine shop tools and surface plates are widely used to assess out of accuracy or warped areas on manufactured parts.

As far as use is concerned, surface plates must be calibrated on a regular basis, at least once to twice a year, but most efficiently and for long-lasting use, it is to be calibrated every six months. Problems usually occur in certain areas having frequent use, so frequent calibration will make sure of chipping, warping, or wear has not observed. An uneven surface will impact the efficient functionality of the whole plate causing errors in measurements and the passing of checked defected parts.

Material Properties of Surface Plate : To make an ideal surface plate, the material must have the following requirements. Must have a high degree of rigidity Resistance to the wear and corrosion Free from warping that is from being Twisted

- Meet DIN876, grade 00 is for inspection room or lab, grade 0 is for workshop.

- Supplied with manufacturers inspection certificate

- Optional accessory: stand for granite surface plate

jack for granite surface plate

Advantages:

• High quality material and precision machining process ensure product quality.

• A traceable QC system is worthy of your trust.

• Efficient warehouse and logistics management ensure your delivery time.

• A two-year warranty makes you without the worries behind.

Granite Surface Plate Calibration Procedure refers to the advanced standards of the leading countries, and its flatness tolerance is in accordance with the JB/T 7975-1999 Surface Plate:

Grade 000 =1x(1+d/1000)/μm

Grade 00 =2x(1+d/1000)/μm

Grade 0 =4x(1+d/1000)/μm

Grade 1 =8x(1+d/1000)/μm

(d is the length of the diagonal)

|

Specification

Length × Width × Thickness (mm)

|

Weight (kgs)

|

Precision Grade (μm)

|

|

000

|

00

|

0

|

1

|

|

300 × 200 × 50

|

17

|

1.5

|

3

|

6

|

12

|

|

300 × 300 × 50

|

19

|

1.5

|

3

|

6

|

12

|

|

400 × 300 × 70

|

25

|

1.5

|

3

|

6

|

12

|

|

400 × 400 × 70

|

48

|

2

|

3.5

|

6.5

|

13

|

|

630 × 400 × 100

|

76

|

2

|

3.5

|

7

|

14

|

|

630 × 630 × 100

|

155

|

2

|

4

|

8

|

16

|

|

800 × 500 × 130

|

156

|

2

|

4

|

8

|

16

|

|

1000 × 630 × 130

|

284

|

2.5

|

4.5

|

9

|

18

|

|

1000 × 750 × 150

|

338

|

2.5

|

5

|

9

|

18

|

|

1000 × 1000 × 150

|

450

|

2.5

|

5

|

10

|

20

|

|

1600 × 1000 × 200

|

963

|

3

|

6

|

12

|

24

|

|

2000 × 1000 × 200

|

1200

|

3.5

|

6.5

|

13

|

26

|

|

1600 × 1600 × 300

|

2312

|

3.5

|

6.5

|

13

|

26

|

|

2000 × 1600 × 300

|

2890

|

3.5

|

7

|

14

|

28

|

|

2500 × 1600 × 300

|

3612

|

4

|

8

|

16

|

32

|

|

3000 × 2000 × 500

|

9030

|

4.5

|

9

|

18

|

36

|

|

4000 × 2000 × 500

|

12040

|

5.5

|

11

|

22

|

44

|

|

6000 × 2000 × 700

|

25284

|

7.5

|

15

|

30

|

60

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!